Blog

Best 10 CNC Lathe Machines for Precision Manufacturing in 2023

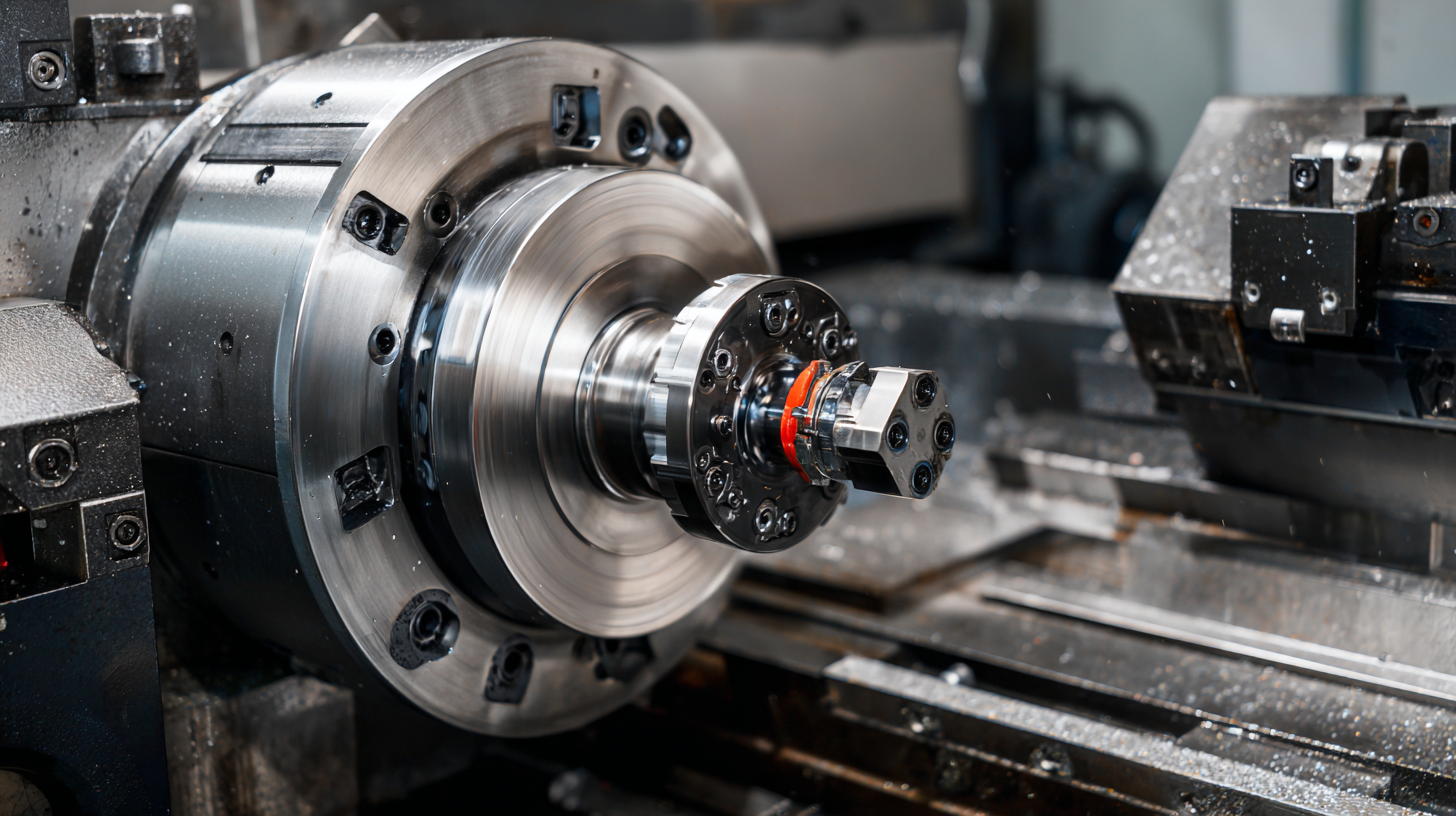

In the fast-evolving landscape of precision manufacturing, the importance of CNC lathe machines cannot be overstated. As industries strive for greater efficiency and accuracy, selecting the right CNC lathe machine is crucial for producing high-quality components. Expert John Smith, a leading authority in CNC technology, once stated, "Investing in the right CNC lathe machine not only enhances production quality but also maximizes operational efficiency." This insight underscores the critical role that advanced lathe machines play in modern manufacturing processes.

As we delve into the best CNC lathe machines of 2023, it is essential to consider the features that distinguish top models from the rest. Precision, durability, and advanced automation technology are key attributes that manufacturers should seek when upgrading or investing in new equipment. The machine's ability to accommodate various materials and perform complex operations can significantly impact a business's productivity and output quality.

In this article, we will explore the top ten CNC lathe machines available this year, examining their specifications, applications, and how they meet the rigorous demands of precision manufacturing. Whether a small workshop or a large-scale industrial facility, choosing the right CNC lathe machine is imperative for staying competitive in today's rapidly advancing market.

Top 5 CNC Lathe Machines for Precision Manufacturing: A 2023 Overview

As the demand for precision manufacturing continues to rise, CNC lathe machines have become indispensable tools across various industries. The technology has evolved, allowing manufacturers to achieve higher levels of accuracy and efficiency, thereby boosting productivity significantly. In 2023, five leading CNC lathe machines have emerged as top choices for precision manufacturing, each offering unique features that cater to different operational needs.

The global CNC machine market is experiencing substantial growth, projected to reach $122.4 billion by 2031. With advancements in digital manufacturing technologies, these machines are transforming how businesses approach production. Particularly in Europe, where the machine tools market is expected to reach $47.75 billion by 2033, the adoption of CNC technology is driving innovations and efficiency in manufacturing. As companies seek to enhance their capabilities, investing in top-tier CNC lathe machines is becoming a strategic priority.

Key Features to Consider When Selecting CNC Lathe Machines

When selecting CNC lathe machines for precision manufacturing, several key features must be considered to ensure optimal performance and efficiency. First and foremost, the spindle speed and torque capabilities play a crucial role in determining the machine's versatility and the types of materials it can handle. A higher spindle speed allows for finer finishes and the capability to work with various materials, while sufficient torque is essential for heavy-duty machining tasks.

Additionally, tooling options, including both static and live tools, are vital for enhancing the machine's functionality. It is advisable to consult with an expert to identify the best tooling options that align with specific manufacturing needs. Tools that can perform multiple operations, such as drilling, milling, and turning, will increase productivity and reduce production lead times. Understanding the machine's construction, precision capabilities, and available upgrades further aids in making an informed decision that aligns with future manufacturing goals.

Performance Metrics: Accuracy and Tolerances in CNC Lathe Operations

When evaluating CNC lathe machines for precision manufacturing in 2023, performance metrics such as accuracy and tolerances play a crucial role. Precision is measured by the machine’s ability to reproduce components within specified dimensions, ensuring that parts fit together seamlessly in their intended applications. High-end CNC lathes typically offer tolerances as tight as ±0.001 inches, making them suitable for intricate projects like aerospace and medical device manufacturing, where even the slightest deviation can lead to failure.

Furthermore, the accuracy of CNC lathes is influenced by various factors, including the type of control system, tooling, and maintenance practices. Advanced CNC machines utilize closed-loop control systems to monitor and adjust the machining process in real-time, reducing errors significantly. Features such as thermal compensation and rigid construction also contribute to maintaining precision over extended production runs. Manufacturers must consider these metrics to select the best CNC lathe that meets their operational demands while ensuring the highest quality standards in their products.

Comparative Analysis of Popular CNC Lathe Brands and Models

In the realm of precision manufacturing, CNC lathe machines play a pivotal role, and choosing the right model can significantly impact production efficiency and quality. According to a recent report by MarketsandMarkets, the CNC lathe machines market is expected to reach $2.3 billion by 2025, driven by increasing demand for automation and precision machining across various industries. This surge has led to a comparative analysis of several popular CNC lathe brands such as Haas, Mazak, and Okuma, which are renowned for their reliability and technological advancements.

Haas Automation, for instance, is widely recognized for its user-friendly interface and robust performance, making it an ideal choice for small to medium-sized manufacturers. Their CNC lathe models, like the Haas ST series, are noted for high-speed capabilities and superior precision, catering to a diverse range of applications. On the other hand, Mazak offers advanced multi-tasking CNC lathes that can handle both turning and machining, thus improving overall productivity. A study by Grand View Research highlighted that firms employing such sophisticated models experienced an up to 30% reduction in cycle times. As manufacturers strive to enhance operational efficiency, selecting the right CNC lathe machine is vital for staying competitive in the evolving landscape of precision manufacturing.

Comparison of Key Features of Top CNC Lathe Machines (2023)

Emerging Technologies in CNC Lathe Machines: Trends to Watch in 2023

The landscape of CNC lathe machines is being transformed by emerging technologies that integrate digitalization, the Internet of Things (IoT), and artificial intelligence (AI). As the manufacturing industry embraces these advancements, productivity and precision have seen significant enhancements across numerous sectors. According to a recent report, the global CNC machine tools market is projected to grow by USD 21.9 billion between 2025 and 2029, largely driven by the increasing demand for high-precision and multi-axis machining centers. This shift signifies a pivotal move towards more automated and efficient manufacturing processes.

Moreover, the market for CNC controllers is also experiencing remarkable growth, with a projected increase from $3.2 billion in 2023 to $7.2 billion by 2033, reflecting a compound annual growth rate (CAGR) of 8.3%. This growth is indicative of a broader trend where tailored solutions powered by AI are redefining the operational efficiencies in machining. As manufacturers look for ways to optimize their processes, the incorporation of IoT technologies is expected to play a crucial role in facilitating real-time data analytics and predictive maintenance, further revolutionizing the CNC lathe landscape.

Related Posts

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

Understanding the Role of CNC Lathe Machines in Modern Manufacturing

-

Exploring the Future of Manufacturing with CNC Milling Machines and Their Innovations

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

Innovative Solutions for Your Small CNC Machine Needs

-

Unlocking the Secrets of Fast CNC Machining for Efficient Production