Blog

How to Choose the Best Small CNC Mill for Your Machining Needs

In recent years, the demand for small CNC mills has surged, driven by advancements in technology and the increasing need for precision machining across various industries. According to a report by Market Research Future, the global CNC machining market is projected to reach USD 100 billion by 2025, with small CNC mills playing a pivotal role in this growth due to their accessibility and efficiency for small-scale operations. The ability to produce complex parts with high accuracy has made these machines indispensable for businesses ranging from prototyping to small manufacturing runs.

Expert in CNC machining, Dr. Emily Chen, emphasizes the importance of selecting the right small CNC mill for specific needs: "Choosing the best small CNC mill can significantly impact your operational efficiency and product quality." With numerous options available, it is crucial for engineers and manufacturers to analyze their unique requirements—such as workspace, material types, and production volume—before making a decision. Understanding the features and capabilities of various small CNC mills can not only enhance productivity but also lead to substantial cost savings in the long run. As more companies venture into precision machining, making an informed choice becomes all the more critical in ensuring competitive advantage in an ever-evolving marketplace.

Factors to Consider When Selecting a Small CNC Mill for Your Workshop

When selecting a small CNC mill for your workshop, several factors are crucial to ensure it meets your machining needs effectively. One of the first considerations is the machine's work envelope, which dictates the maximum size of material you can work with. According to a report by Market Research Future, nearly 39% of manufacturers prioritize the work area size when purchasing CNC machines, emphasizing its importance in accommodating various projects. Ensuring your chosen mill has a suitable work envelope can prevent limitations in your production capabilities.

Another key factor is the material compatibility of the CNC mill. Different mills are optimized for specific materials, including aluminum, steel, and plastics. A survey conducted by the International Manufacturing Technology Show highlights that 56% of shops regularly switch between materials, making versatility a significant advantage. Small CNC mills with advanced features, such as variable speed controls and robust tooling, can handle diverse materials while maintaining precision and finish quality. This flexibility is essential for workshops aiming to cater to a wide range of client demands or projects.

Essential Features That Define the Best Small CNC Mills

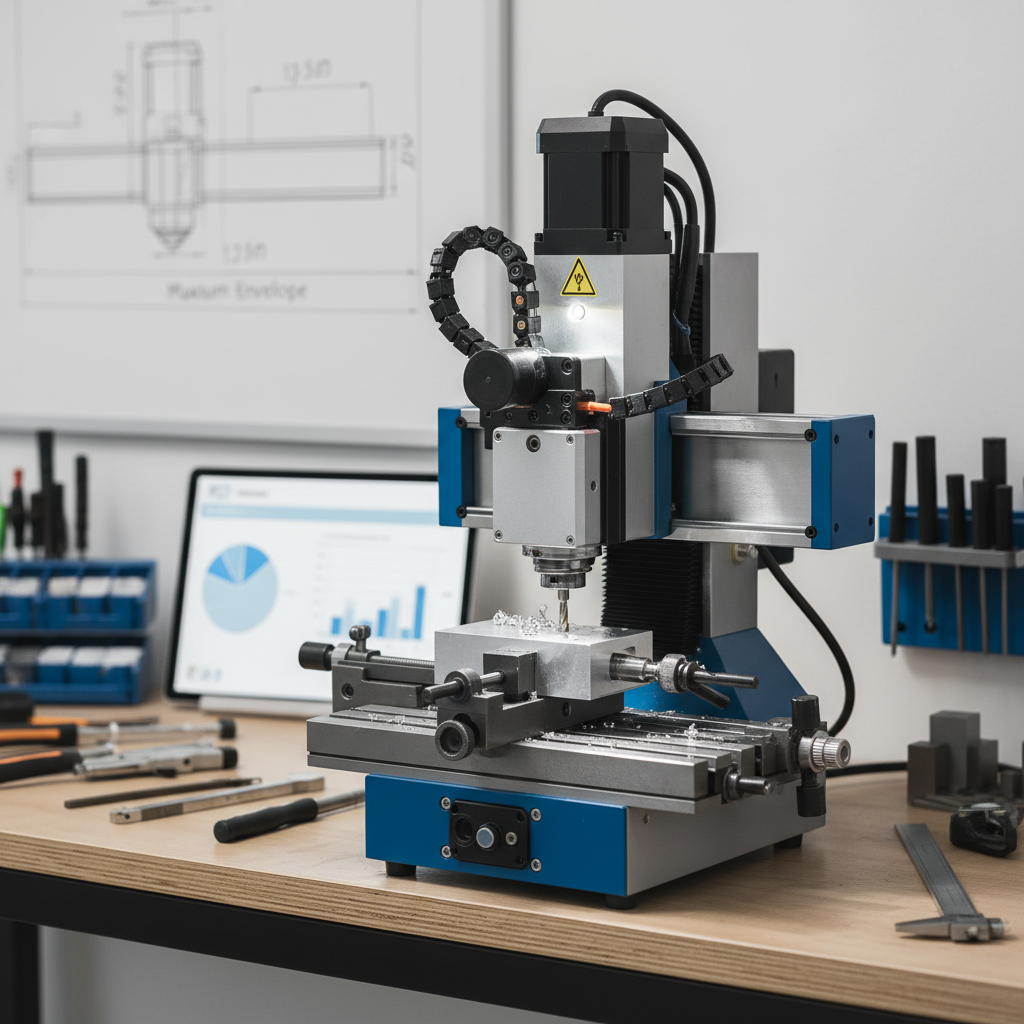

When selecting the best small CNC mill for your machining needs, it’s crucial to focus on essential features that will enhance both functionality and efficiency. One of the most significant features to consider is the milling capacity, which includes the maximum size of the workpiece and the travel distance of the spindle along its axes. A mill with adequate travel dimensions and a strong spindle motor will allow you to tackle a wider variety of projects without compromising precision.

Another key feature to evaluate is the type of control system employed by the CNC mill. A user-friendly interface, whether it’s a robust computer software system or manual controls, can greatly affect your productivity. Look for machines that offer intuitive programming, as well as compatibility with various CAD/CAM software. Additionally, consider the machine's construction and stability; a rigid frame will reduce vibrations and improve the overall machining accuracy. By carefully assessing these characteristics, you can choose a small CNC mill that aligns with your specific machining requirements.

How to Choose the Best Small CNC Mill for Your Machining Needs - Essential Features That Define the Best Small CNC Mills

| Feature | Description | Importance |

|---|---|---|

| Spindle Speed | The maximum speed at which the spindle can rotate, measured in RPM. | High spindle speeds are essential for efficient machining of softer materials. |

| Working Area | The maximum size of material that can be machined, defined by XYZ dimensions. | A larger working area allows for more versatility in projects. |

| Accuracy | The degree to which the machine can replicate dimensions and tolerances. | Higher accuracy is crucial for tight tolerance applications. |

| Tool Change System | The mechanism that allows for automatic tool changes during machining. | Automatic tool changes save time and increase productivity. |

| Control Software | The software used to control the CNC machine's operations. | User-friendly software is essential for ease of programming and operation. |

| Build Quality | The materials and construction of the CNC mill affecting its durability. | A well-built machine lasts longer and performs reliably under stress. |

| Power Consumption | The amount of power the CNC mill requires to operate effectively. | Low power consumption reduces operational costs and increases efficiency. |

| Safety Features | Safety mechanisms to protect the operator and machine. | Essential for ensuring safe operation in a workshop environment. |

Comparative Analysis of Popular Small CNC Mill Brands and Models

When selecting a small CNC mill, understanding the competitive landscape of brands and models is crucial. A recent industry report highlighted that the global CNC machining market is projected to grow at a CAGR of 5.2% from 2022 to 2028, driven by the increasing demand for precision machinery in various sectors, including aerospace and automotive. Popular brands such as Haas, Tormach, and Vision Machinery have emerged as leaders in the small CNC milling segment, each offering unique features tailored to specific machining needs.

Haas Automation, for example, is renowned for its robust and user-friendly CNC mills, making it a favorite among small to medium-sized enterprises. Their Mini Mill series is particularly praised for its affordable pricing and versatile capabilities. Tormach, on the other hand, is gaining traction due to its modular designs and comprehensive support resources, which appeal to hobbyists and small shops. Data from a recent survey indicated that 78% of small machine shop owners prioritize ease of use and customer service when selecting a CNC mill, highlighting the importance of brand reputation and product reliability in their purchasing decisions.

Cost vs. Performance: Finding the Right Balance in Small CNC Milling Machines

When selecting a small CNC mill, the balance between cost and performance is paramount. While many buyers may be tempted to opt for the most affordable option available, it's essential to consider whether that choice aligns with your machining needs. A low-cost machine might save money upfront but could lead to higher operational costs over time due to inefficiencies and the need for frequent repairs or replacements. Performance characteristics, such as precision, speed, and versatility, typically correlate with higher-priced models, making it crucial to weigh these factors against your budget constraints.

Investing in a higher-performance small CNC mill can yield greater returns in the long run. Such machines not only improve productivity through faster cycle times but also typically offer better build quality, resulting in finer tolerances and longer machine lifespans.

It's advisable to evaluate your specific applications and the materials you'll be working with to ensure that the mill can handle the demands. Ultimately, finding the right balance between cost and performance means carefully assessing your priorities and the potential impact on your workflow, ensuring you derive maximum efficiency from your investment.

User Reviews and Feedback: How to Gauge the Best Small CNC Mill Options

When considering the best small CNC mill for your machining needs, user reviews and feedback are essential resources that can provide valuable insights. According to a 2022 report by the Manufacturing Association, 78% of customers rely on online reviews when making purchasing decisions, underscoring the importance of community experiences in selecting machinery. User feedback often highlights not just the performance of the CNC mill, but also aspects such as ease of use, software compatibility, and customer support from manufacturers.

**Tips:**

1. Look for CNC mills that have consistently positive reviews across multiple platforms to ensure reliability.

2. Pay attention to any common complaints regarding maintenance or downtime, as these can significantly impact your operations.

Moreover, industry professionals recommend joining forums and discussion groups dedicated to CNC machining. Engaging in these communities can provide firsthand experiences and recommendations that are often not covered in product descriptions. According to a 2023 study by TechMachinery Insights, 65% of machinists reported making better choices for their businesses by leveraging peer feedback, emphasizing the role of shared knowledge in the decision-making process.

Related Posts

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

Understanding the Role of CNC Lathe Machines in Modern Manufacturing

-

The Future of Small CNC Mills in Precision Manufacturing with Industry Insights

-

Innovative Solutions for Your Small CNC Machine Needs

-

5 Smart Tips for Choosing the Right Small CNC Mill for Your Business Needs

-

How to Optimize Your Production Line with Fast CNC Machining Solutions