Blog

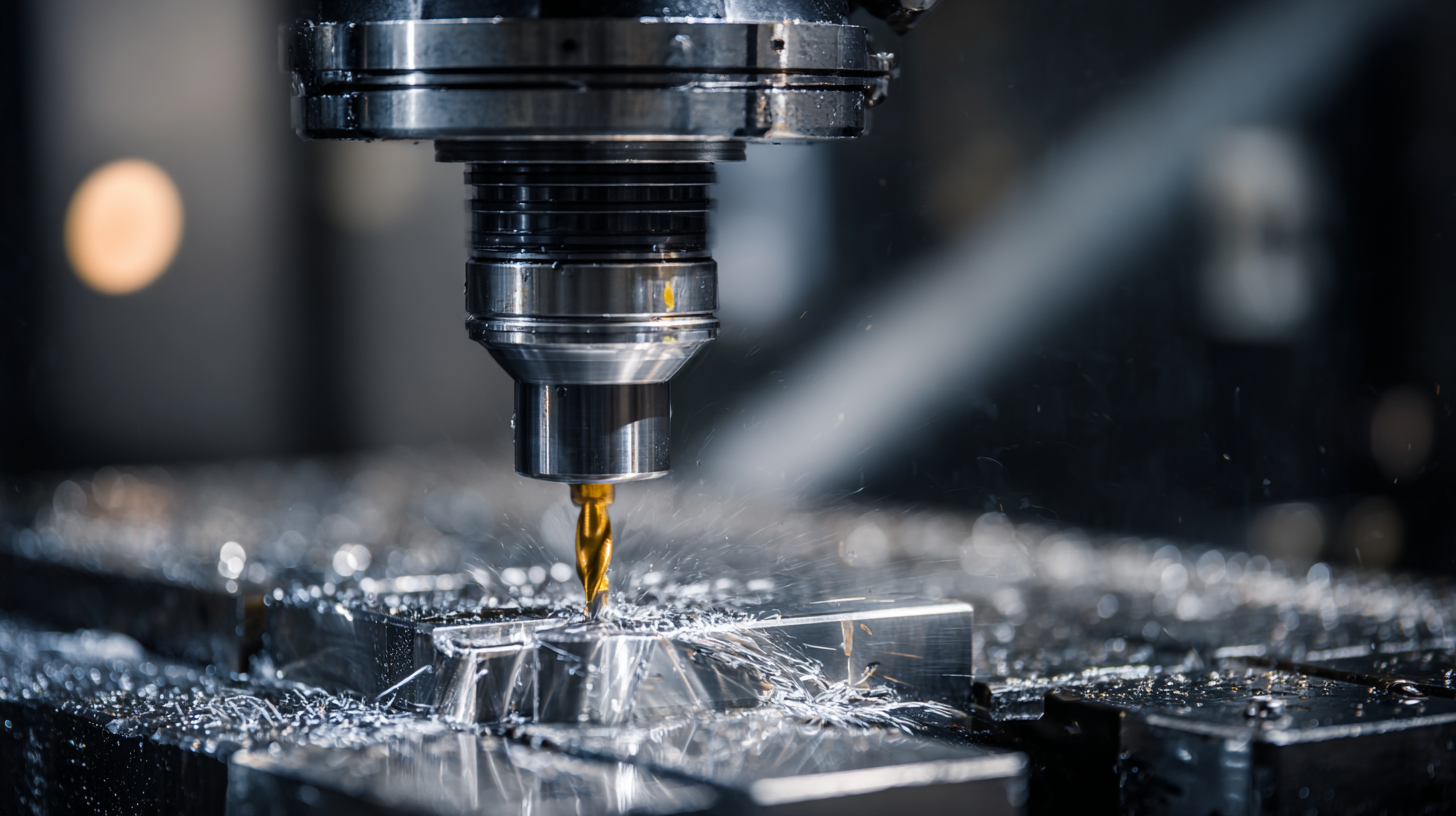

How to Enhance Precision in CNC Metal Fabrication Techniques

In the rapidly evolving landscape of manufacturing, the precision of CNC metal fabrication techniques has become a pivotal factor influencing product quality and operational efficiency. According to a report by the International Federation of Robotics, the global market for CNC machines is projected to reach $100 billion by 2025, underscoring the increasing reliance on advanced technologies in metal fabrication. With the integration of sophisticated software and innovative tooling, CNC metal processes can achieve tolerances within ±0.001 inches, significantly minimizing material waste and enhancing product consistency.

As industries demand more complex geometries and tighter specifications, mastering precision in CNC metal fabrication is not merely an option—it is essential for maintaining competitive advantage in the market. This article delves into the methodologies and best practices to elevate precision in CNC metal fabrication, ultimately driving productivity and innovation.

Best Practices for CNC Machine Calibration and Maintenance

Maintaining precision in CNC metal fabrication largely hinges on the regular calibration and upkeep of CNC machines. Proper calibration ensures that the machine operates within specified tolerances, which is crucial for achieving the desired dimensions in metal parts. To calibrate CNC machines effectively, operators should monitor key parameters such as axis movement, backlash, and spindle speed. Employing specialized calibration tools and software can help detect discrepancies and guide adjustments to restore accuracy.

In addition to calibration, routine maintenance is essential for the longevity and reliability of CNC machines. This includes regular cleaning, lubrication of moving parts, and inspection of wear components like belts and bearings. Establishing a maintenance schedule can help preempt potential issues, reducing downtime and enhancing productivity. Moreover, training operators on best maintenance practices amplifies the overall effectiveness, ensuring that machines run smoother and more precisely throughout their operational life.

Enhancing Precision in CNC Metal Fabrication Techniques

This chart illustrates the impact of regular CNC machine calibration on production accuracy measured by the percentage of achieved tolerances in various categories over a period of six months.

Advanced Tooling Techniques for Improved Accuracy in Metal Fabrication

In the realm of CNC metal fabrication, employing advanced tooling techniques is paramount for enhancing accuracy. Recent studies highlight the importance of integrating in-process monitoring strategies, which can effectively measure crucial parameters such as force, geometry, and temperature during metal forming processes. By utilizing real-time data collection methods, manufacturers can significantly reduce defects and improve dimensional accuracy, ultimately leading to higher quality metal components.

Moreover, the precision tool market is poised for remarkable growth, projected to reach USD 346.38 billion by 2033, up from USD 231.78 billion in 2025. Such growth underscores the escalating demand for innovative fabrication technologies. Techniques like minimum quantity lubrication (MQL), as analyzed in recent reviews, are also gaining traction for their ability to improve the machinability of difficult-to-machine alloys, ensuring optimal performance in machining operations. As the industry evolves, the integration of these advanced methods alongside sophisticated tools will be essential in driving improvements in accuracy and overall efficiency within CNC metal fabrication.

Integrating Software Solutions for Enhanced Precision Control

In the world of CNC metal fabrication, the integration of advanced software solutions plays a pivotal role in enhancing precision control. Recent industry reports indicate that the adoption of cutting-edge software can improve machining accuracy by up to 20%. These advanced systems allow for real-time monitoring and adjustment of machining parameters, significantly reducing the likelihood of errors that can arise during the fabrication process. By employing software that incorporates AI and machine learning technologies, manufacturers can optimize toolpath strategies and predict tool wear, leading to more precise outcomes.

Moreover, sophisticated software tools facilitate better data management and analysis, which are crucial for maintaining high precision in CNC operations. For instance, the use of CAD/CAM software enables seamless communication between design and manufacturing processes, ensuring that specifications are accurately met. According to a recent survey by the Manufacturing Institute, companies that utilize these integrated software solutions have reported a 30% reduction in production waste due to increased precision and predictability in their machining processes. As the industry continues to evolve, the emphasis on integrating software for enhanced precision will only grow stronger, providing a competitive edge to those who embrace these technologies.

Utilizing Simulation Technology to Optimize CNC Machining Processes

In the realm of CNC metal fabrication, simulation technology has emerged as a vital tool for enhancing precision and optimizing machining processes. According to a 2022 report by Wohlers Associates, the adoption of advanced simulation tools in CNC machining can improve production efficiency by up to 30%, minimizing material waste and reducing machining time. By leveraging these technologies, manufacturers can create comprehensive virtual models of machining operations, allowing for real-time adjustments and inspections of the machining process before actual production begins.

Additionally, implementing simulation can significantly decrease the risk of errors that often contribute to costly rework. The same report highlights that companies utilizing simulation technologies experience a 25% reduction in defects during production phases. This improvement stems from the ability to preemptively identify potential issues by testing various machining parameters and setups in a controlled virtual environment. As the industry progresses toward more automated and intelligent manufacturing solutions, embracing simulation technology is not just an option but a necessity for achieving unparalleled precision in CNC metal fabrication.

Implementing Quality Control Measures for Consistent Fabrication Outcomes

Implementing quality control measures is essential for achieving consistent outcomes in CNC metal fabrication. One effective approach is the establishment of standardized operational procedures that define each step of the fabrication process. This includes setting specific tolerances and guidelines for machining that minimize variability and ensure that parts are produced within the desired specifications. Regular training of CNC operators on these standards is also crucial, as it empowers them to recognize and address issues proactively, thereby enhancing the overall precision of the fabrication process.

Another vital aspect of quality control is the incorporation of advanced monitoring technologies, such as real-time data analytics and feedback systems. By using tools like CNC machine sensors and software that track performance metrics, manufacturers can quickly identify deviations from pre-established norms. This not only helps in timely adjustments during the fabrication process but also facilitates a continuous improvement culture where insights gained from data analysis can lead to refined processes. Thus, a robust quality control framework is fundamental to ensuring that CNC metal fabrication yields consistent and high-quality results.

Related Posts

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

Understanding the Role of CNC Lathe Machines in Modern Manufacturing

-

The Future of Small CNC Mills in Precision Manufacturing with Industry Insights

-

Innovative Solutions for Your Small CNC Machine Needs

-

How to Optimize Your CNC Router Machine for Maximum Efficiency