Blog

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques

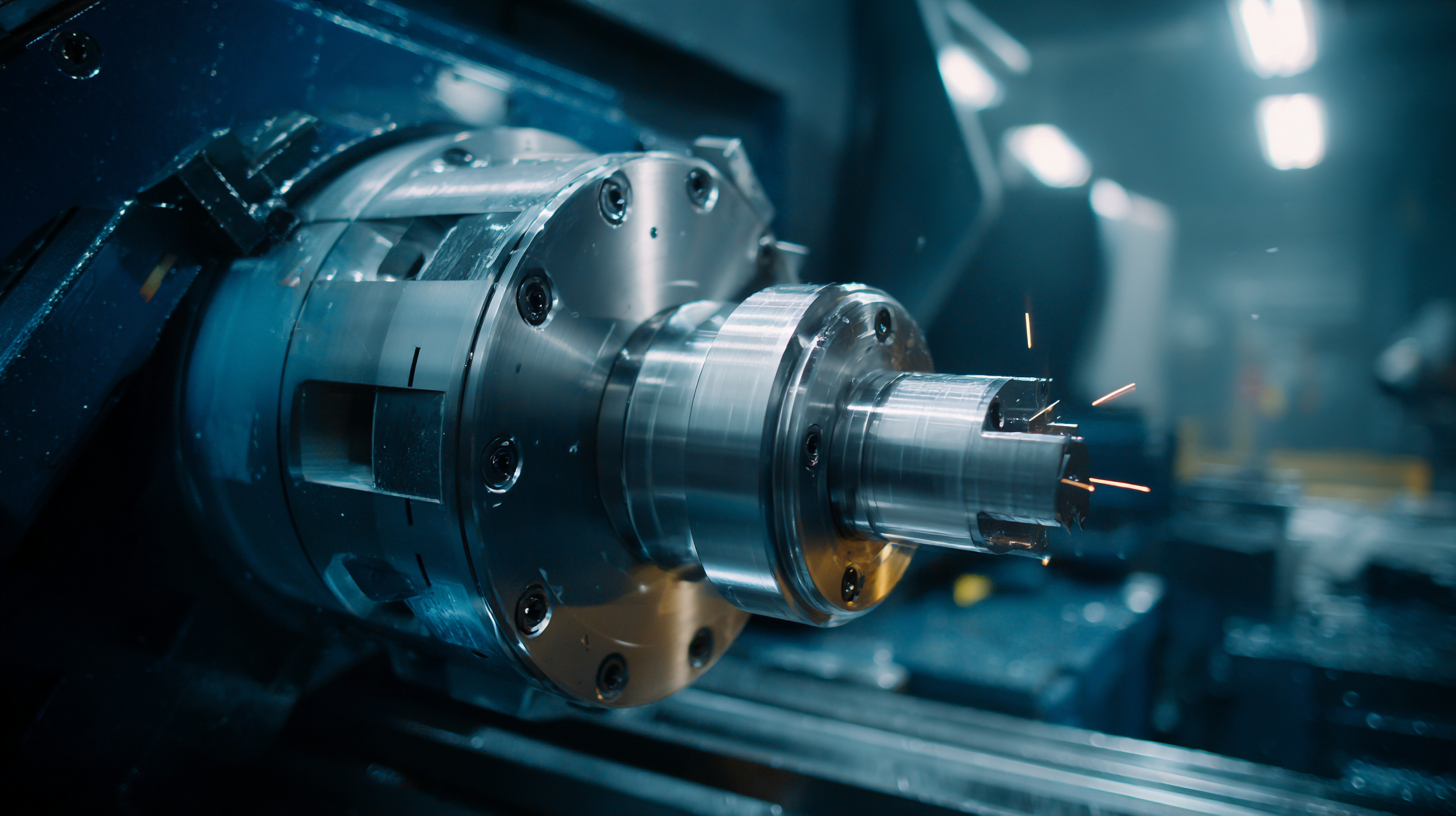

The evolution of manufacturing techniques has significantly influenced the role of CNC machining parts in industry. As reported by the International Federation of Robotics, the global market for CNC technology is projected to reach $100 billion by 2025, reflecting an increasing reliance on precision-engineered components across various sectors. CNC machining parts are becoming indispensable due to their capability to deliver high accuracy, reduced production time, and enhanced efficiency compared to traditional manufacturing methods. In addition, a study by Deloitte indicates that the adoption of advanced manufacturing technologies, including CNC machining, can lead to productivity gains of up to 30%. As industries continue to innovate, the integration of CNC machining parts is poised to redefine standards of quality and performance, driving the future of modern manufacturing techniques.

The Evolution of CNC Machining Technology in Contemporary Manufacturing

The evolution of CNC machining technology is reshaping the landscape of contemporary manufacturing. Innovations such as artificial intelligence and robotics are revolutionizing how manufacturers approach processes, enhancing precision and productivity. The incorporation of smart manufacturing techniques allows CNC machines to operate with unprecedented efficiency, achieving tighter tolerances and faster turnaround times. As industries embrace these advancements, the role of CNC machining becomes increasingly critical in meeting modern demands for custom and high-quality components.

Tips for manufacturers looking to adopt these new CNC technologies include investing in employee training to ensure that the workforce is proficient in the latest systems. Staying updated with advancements in CAD and inspection software can also significantly improve quality assurance processes, reducing errors and enhancing production outcomes. Furthermore, exploring the integration of nanotechnology in machining can lead to the discovery of new materials and methods, pushing the boundaries of what is possible in manufacturing.

As we move forward, the CNC machine market is projected to grow steadily, emphasizing the continuous need for adaptability within the industry. Manufacturers who leverage these innovations will not only increase their competitiveness but also redefine the standards of excellence in machining and production.

Integrating Digital Tools for Enhanced CNC Machining Efficiency

The integration of digital tools into CNC machining processes has revolutionized modern manufacturing techniques, leading to enhanced efficiency and productivity. By incorporating advanced software and automation, manufacturers can streamline workflows, reduce cycle times, and minimize human errors. These digital technologies enable real-time monitoring and adjustments, allowing for more precise machining and improved quality control throughout the production process.

Moreover, the shift towards data-driven decision-making has empowered manufacturers to optimize their operations further. Utilizing analytics and machine learning algorithms, companies can predict maintenance needs, reducing downtime and extending the life of CNC equipment. This proactive approach not only enhances operational efficiency but also contributes to more sustainable manufacturing practices by optimizing resource usage and reducing waste. As industries continue to embrace these digital advancements, the future of CNC machining parts looks promising, positioning manufacturers at the forefront of innovation.

Best Practices in CNC Machining: Innovations and Techniques

In the rapidly evolving realm of manufacturing, CNC machining continues to play a pivotal role in enhancing precision and efficiency. One of the best practices in this field is the incorporation of advanced software solutions, such as CAD/CAM systems, which streamline the design and production processes. These tools enable manufacturers to create intricate parts with sophisticated geometries while minimizing human error. By integrating real-time data monitoring, companies can also optimize machine performance and reduce downtime, leading to increased productivity.

Another innovative technique making waves in CNC machining is the adoption of additive manufacturing in conjunction with traditional subtractive processes. This hybrid approach allows for the creation of complex components that would be difficult or impossible to achieve with extrusion or milling alone. Additionally, the use of smart tools equipped with IoT capabilities enhances maintenance routines, allowing for predictive analytics that can significantly extend machinery life cycles. As the manufacturing landscape continues to shift, these innovations represent a commitment to efficiency and quality in CNC machining.

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques - Best Practices in CNC Machining: Innovations and Techniques

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| 5-Axis Machining | A CNC machining technique that utilizes five axes for cutting. | Increased precision, reduced setup time, and the ability to create complex geometries. | Aerospace, automotive, and medical device manufacturing. |

| Additive Manufacturing Integration | Combining CNC machining with additive processes for enhanced capabilities. | Ability to create complex parts with reduced waste and weight. | Prototyping and custom parts in various sectors. |

| Automated Tool Changer | A system that automatically changes machine tools during operation. | Improves efficiency and reduces downtime. | Mass production and high-volume manufacturing. |

| Computer-Aided Design (CAD) Integration | Using advanced software for precise design before machining. | Enhanced design flexibility and accuracy. | Custom part design across various industries. |

| Real-Time Monitoring and Analytics | Using IoT devices to monitor the machining process in real-time. | Increased productivity, predictive maintenance, and reduced errors. | Manufacturing plants, quality control processes. |

The Role of Automation and AI in CNC Machining Parts Production

The integration of automation and artificial intelligence (AI) in CNC machining parts production is heralding a transformative era in modern manufacturing. Companies like LimitlessCNC are at the forefront of this revolution, utilizing a significant investment to develop AI agents aimed at enhancing precision manufacturing processes. By leveraging advanced algorithms and machine learning, these innovative solutions enable more efficient production workflows, driving down costs and reducing the time from design to finished part. This shift not only promises to increase output but also to bring manufacturing back to Western economies.

As the demand for precision parts escalates, the market for CNC machining is predicted to grow substantially, with projections indicating a rise in the sector's valuation in the coming years. This growth is further supported by partnerships between tech firms and manufacturing leaders, fostering the development of AI-driven manufacturing solutions that enhance productivity and bridge existing skills gaps in the workforce. The evolution of CNC programming through automation tools is also contributing to this transformation, ensuring that manufacturers are well-equipped to meet the complexities of today's production environments.

Sustainability in CNC Machining: Future Trends and Environmental Impact

The integration of sustainability into CNC machining is becoming increasingly crucial as industries strive to reduce their environmental footprint. Future trends indicate a strong reliance on advanced technologies, such as artificial intelligence (AI), to enhance efficiency and minimize waste. For instance, recent studies show that AI can significantly improve production processes by optimizing machine operations, thereby reducing energy consumption while maintaining high precision in manufacturing. This technological transformation is expected to contribute to the broader goal of sustainable manufacturing environments in the upcoming years, with industry analysts predicting a shift towards more eco-friendly practices that do not compromise quality.

Furthermore, as we look toward 2025, the emergence of sustainable economies emphasizes the need for manufacturers to adopt environmentally-responsible practices. Reports suggest that companies implementing sustainability measures can expect enhanced market performance and a competitive edge. By focusing on key traits such as long-term environmental wellness, social equity, and durable growth, the CNC machining industry is poised to not only meet regulatory requirements but also anticipate consumer demand for sustainable products. Such strategic shifts not only align with ESG (Environmental, Social, and Governance) principles but also resonate with the evolving expectations of stakeholders and customers alike.

Related Posts

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

Unlocking the Secrets of Fast CNC Machining for Efficient Production

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

How to Choose the Best Small CNC Machine for Your Business Needs

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes

-

The Evolution of CNC Routers Transforming Modern Manufacturing Processes